OQL – Overall Quality Level

OQL – Overall Quality Level

OQL – Overall Quality Level is a metric used to measure the quality performance of a supplier. It represents the percentage of non-conforming parts or defects found during an audit or inspection compared to the total inspected quantity.

How OQL is Calculated

OQL = ( Non-Conforming Units ÷ Total Units Inspected ) × 100

Example Calculation:

Non-Conforming Units = 5

Total Units Inspected = 1,000

OQL = (5 ÷ 1,000) × 100

OQL = 0.5%

What OQL – Overall Quality Level Tells You

- Lower OQL (%) = Better Quality → Fewer defects, better supplier performance.

- Higher OQL (%) = Poor Quality → More defects, potential quality issues.

Why OQL – Overall Quality Level Matters

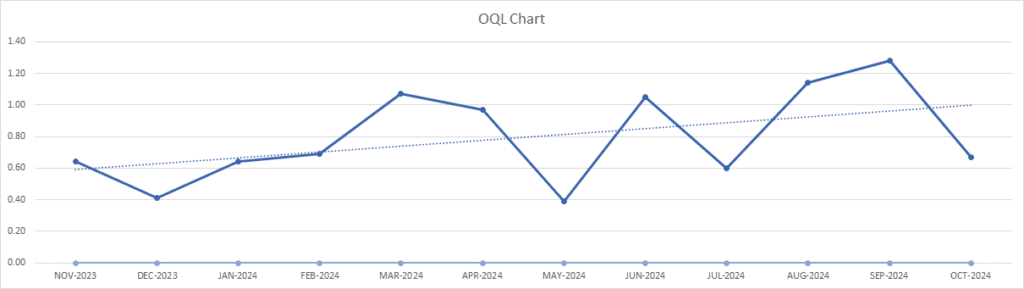

- Helps assess supplier performance over time.

- Supports data-driven decision-making for supplier selection.

- Identifies trends and recurring quality issues.

- Encourages suppliers to improve processes and reduce defects.

How to Set Up OQL – Overall Quality Level Targets for Suppliers

Setting Overall Quality Level (OQL) targets helps ensure supplier quality meets your company’s standards while encouraging continuous improvement. Follow these steps to establish effective targets:

1. Define Acceptable Quality Standards

- Review Industry Standards – Use benchmarks like ISO 9001, Six Sigma, or AQL (Acceptance Quality Limit) to guide expectations.

- Align with Business Needs – Consider customer expectations, product criticality, and cost impact when setting OQL limits.

- Set Different OQL Targets for Different Products – High-risk or critical components (e.g., aerospace or medical parts) may require stricter OQL limits than low-risk items.

2. Analyze Historical Data

- Review Past OQL Trends – Look at supplier performance over the last 6-12 months to establish a realistic baseline.

- Identify Top-Performing Suppliers – Use their OQL as a benchmark for others.

- Determine Process Capability (Cp & Cpk) – Ensure the supplier can consistently meet the proposed OQL target.

3. Set Tiered OQL Targets

Instead of a single pass/fail limit, use tiered targets:

| Performance Level | OQL Target (%) | Action |

|---|---|---|

| Excellent | ≤ 0.1% | Reward supplier, less frequent audits |

| Acceptable | 0.1% – 0.5% | Standard monitoring, regular audits |

| Needs Improvement | 0.5% – 1.0% | Require corrective action plan |

| Unacceptable | > 1.0% | Escalation, possible supplier reevaluation |

4. Implement Corrective Action Requirements

- If a supplier exceeds the OQL limit, require them to:

- Conduct root cause analysis (e.g., 5 Whys, Fishbone Diagram).

- Submit a corrective action plan (CAPA) detailing how they will reduce defects.

- Show improvement within a defined period (e.g., next 3 audits).

5. Continuously Monitor and Adjust Targets

- Review OQL performance quarterly and adjust based on supplier improvements.

- Consider tightening targets if suppliers consistently outperform them.

- Use incentives (e.g., reduced inspections or bonuses) for suppliers who maintain excellent quality.