LLMS – Lyons Laboratory Management System - LIMS for Material, Textile & Apparel testing

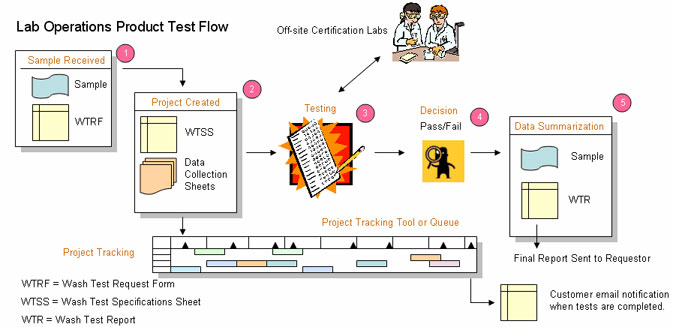

Lyons Laboratory Management System (LLMS) streamlines the material, garment, and fabric laboratory testing process. This cloud-based mobile and web LIMS system is designed to quickly and comprehensively process testing jobs in material and apparel testing laboratories. Technicians enter product test results from a built-in library of standard test methods, and the system automatically performs and reports pass/fail determinations using a versatile, robust reporting engine. LLMS also supports the entry of test results from outsourced laboratories, remote job requests from customers, and extensive data analysis capabilities. Additionally, users can easily view how work is distributed within the laboratory at specific steps of the testing process and monitor turn times. LLMS helps you manage your laboratory data easily and efficiently by storing, processing, reporting, and analyzing it in a secure, cloud-based environment.

Increase efficiency.

Textile and apparel manufacturing laboratory processes are traditionally very labor-intensive. LLMS increases efficiency by simplifying data capture and automating data analysis. Lyons Laboratory Management System swiftly creates flexible final testing evaluation reports and integrates data from external database systems. Lyons Laboratory Management System LLMS is fully user-managed and offers flexible, comprehensive query capabilities for test, supplier, and laboratory information. The system easily customizes to accommodate non-standard testing methods and procedures, and it uses non-proprietary technology for its database and code infrastructure. As with all Lyons software systems, laboratory staff secure and fully manage all content without relying on “hard-coded” elements, and appropriate manufacturer staff securely and fully manage content.

Qualitative and Quantitative tests

LLMS conducts a plethora of qualitative and quantitative material and textile testing standards tests according to recognized industry and international standards such as AATCC, ASTM, CTS, FTMS, MER, and TAPPI. LLMS supports any standards or regulations applicable to the materials being tested. Here you can find a list of standards which are supported by LLMS.

Potential Benefits of Lyons Laboratory Management System LLMS Implementation

When looking at potential benefits of installing a LLMS, most ultimately result in saving money. This savings can not only help justify the decision, but also underscore the need to prioritize rolling out certain critical features first.

Installing a LLMS can help your company:

- Increase number of samples processed

- Decrease sample processing time

- Cut number of analyst hours needed for processing

- Reduce error rates

- Reduce frequency of process inspection

- Speed release of manufactured products

- Automate customer service needs by offering self-service, read-only access to sample status and test results

In addition, a few intangible benefits include:

- Achieving and demonstrating compliance more easily

- Detecting and correcting errors earlier

- Improving customer satisfaction

The system allows administrators to configure it for use behind a company firewall or host it as a web-based system. All that is required for user access is a Tablets (Android or Apple iPad), or Windows browser, and access to the LLMS cloud based system. Product testing data may come from outsourced and in-house testing locations. Users with system administration rights and privileges completely control security and content. A final report of test findings comes from a flexible report generator that may include as much content as desired, including embedded images, attached documents, etc. Final test reports are electronically sent to product test requestors when a job is completed.

Sample management / accessioning / tracking

Laboratory management

Understanding the overhead and capacity that your team can support is key to determining timelines, reporting on turnaround times, and resourcing projects. You can review complete overview of samples that are queued and their status.

Workflow capabilities

Users can quickly build workflows which map to actual laboratory processes, automating decisions and actions and reducing the need for user intervention. Labs can easily adapt to new methods and process changes.

Mobile LIMS

LLMS – Lyons Laboratory Management System mobile LIMS application makes features available via tablet, wherever there is an available internet/network connection, so you can take the LIMS with you to execute methods and collect and process samples.

Dashboards and data visualization

Data can be visualized in the system through reports and dashboards enabling laboratories to track overall laboratory performance and assigned work.

Reporting and data analytics

Information in the LIMS can be reported on, shared, analyzed, and audited. All relationships and metadata are captured, enabling users to work with data in context.

Data archival

Ensure proper electronic records retention and data archival to comply with the latest requirements.

Collaborative work environment

Collect and share data securely in real-time with collaborators in your lab or across the globe.

Cloud or on-premises deployment

The option to deploy using a LLMS – Lyons Laboratory Management System managed infrastructure including servers, OS and database, backup, disaster recovery and information security monitoring, reducing initial hardware and ongoing IT costs.

Security

Additional product training videos for

Latest News

- Lyons Laboratory Management System (LLMS) to use Azure Authentication https://www.lyonsinfo.com/llms-to-use-azure-authentication/

- Lyons Laboratory Management System (LLMS) releases enhancements in mobile and web platforms to increase productivity. https://www.lyonsinfo.com/llms-enhancements-in-mobile/

- Lyons Information Systems, Inc. creates a new Laboratory Management System (LLMS) https://www.lyonsinfo.com/textile-testing-lims-llms/

- Williamson-Dickie Mfg. Co. chooses LLMS as their in-house fabric and garment laboratory testing system.

- Cintas Manufacturing Co. chooses LLMS as their automated laboratory product testing system.

- Williamson-Dickie Mfg Co. implements LLMS at its laboratory in Ft. Worth, TX

- Apparel Magazine features LLMS in use at the Cintas Corporation testing laboratory.

- CINTAS: SERVING STARBUCKS AND MCDONALDS WITH A SMILE https://risnews.com/cintas-serving-starbucks-and-mcdonalds-smile

- Lyons Information Systems Launches New Laboratory Management Software. Lyons Information Systems, a provider of enterprise quality software systems for the apparel industry, has added a laboratory management system to its suite of products. Lyons Laboratory Management System (LLMS) streamlines the garment and fabric laboratory testing process. It is a web-based system that is designed for quick yet comprehensive throughput of product testing in an apparel testing laboratory. From a built-in library of standard test methods, technicians enter product test results from which pass/fail determinations are automatically performed and reported using a versatile and robust reporting engine. LLMS also provides entry of test results data from outsourced laboratories, remote job requests from customers, turn time reporting and extensive data analysis capabilities. In addition, users may easily view the distribution of work within the laboratory at critical points within the testing process. https://risnews.com/lyons-information-systems-launches-new-laboratory-management-software