First Aid and Safety (FAS) outbound audit Lyons Quality Audit Tracking System

First Aid and Safety FAS outbound audit Lyons Quality Audit Tracking System

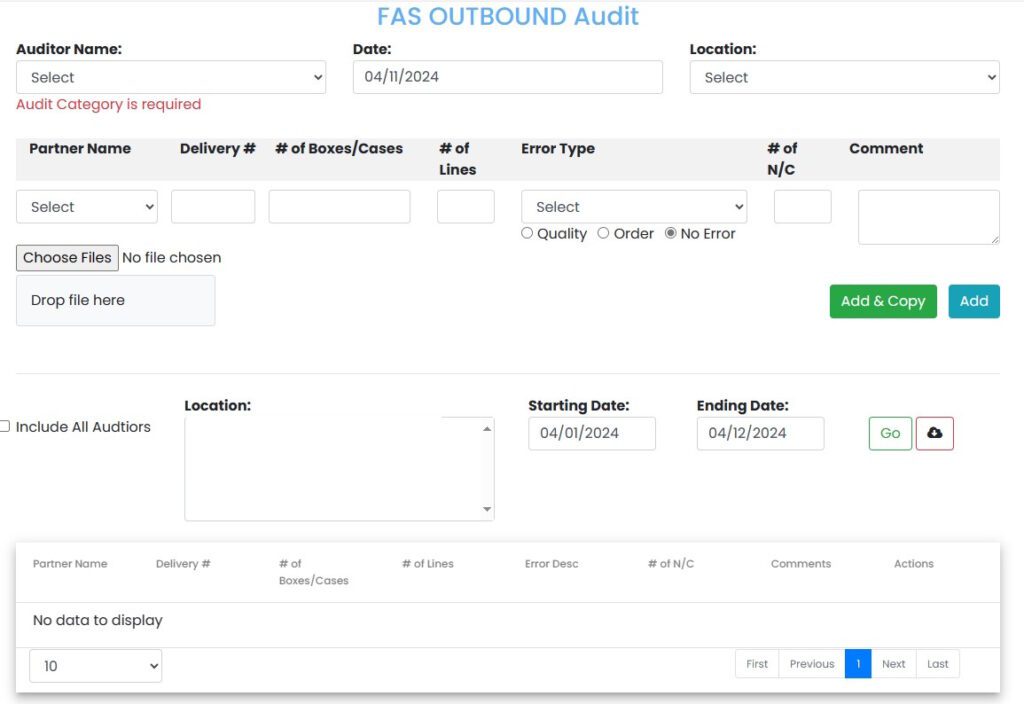

First Aid and Safety FAS outbound audit is an assessment conducted to evaluate various aspects of outbound operations within an organization using Lyons Quality Audit Tracking System (LQATS). Outbound operations typically involve activities such as order processing, picking, packing, shipping, and delivery of goods or services to customers or other recipients. The primary objective of an outbound audit is to ensure the efficiency, accuracy, and compliance of these operations with organizational standards, customer requirements, and regulatory guidelines.

Outbound Audit Outline

Order Processing:

The audit evaluates how accurately and efficiently the organization processes orders. It examines order entry, confirmation, and fulfillment procedures. Auditors review order processing systems, documentation, and workflows to ensure timely and correct order processing.

Inventory Management:

The audit assesses the effectiveness of inventory management practices in outbound operations. It focuses on inventory accuracy, stock availability, and tracking. Auditors conduct physical inventory counts, reconcile inventory records, and identify discrepancies or variances.

Picking and Packing:

The audit evaluates the picking and packing processes to verify that team members select, pack, and prepare the correct items for shipment. Auditors assess the accuracy of picking lists, the quality of packing materials, and the completeness of packing instructions.

Quality Control:

The audit reviews quality control measures implemented in outbound operations to ensure products meet specified quality standards before shipment. Auditors inspect products for defects, conduct quality checks, and implement corrective actions for any identified quality issues.

Regulatory Compliance:

The audit verifies compliance with relevant regulatory requirements, industry standards, and legal obligations related to outbound operations. This includes checking adherence to shipping regulations, customs requirements, product labeling standards, and data privacy regulations.

Performance Metrics:

The audit analyzes key performance indicators (KPIs) and metrics to measure the effectiveness of outbound operations. Metrics may include order accuracy, on-time delivery rates, order cycle times, and customer satisfaction scores.

Continuous Improvement:

The audit identifies opportunities for process improvements, efficiency gains, and cost savings in outbound operations. Auditors recommend implementing best practices, streamlining workflows, and leveraging technology solutions to optimize processes and enhance overall performance.

Reporting and Documentation:

The audit team documents findings in the Lyons Quality Audit Tracking System, summarizing observations, findings, recommendations, and action plans for improvement. This report is shared with stakeholders, including management, operations teams, and quality assurance personnel, to facilitate communication and collaboration in addressing audit findings and driving continuous improvement in outbound operations.

Overall, outbound audits play a critical role in ensuring the efficiency, accuracy, and compliance of outbound operations. They also identify opportunities for improvement and optimization to enhance customer satisfaction and organizational performance.